Continuous technological changes, shorter life cycles for products and services and changes in customer habits are all obstacles most companies face. The current COVID-19 pandemic has not only exacerbated some of these, but also forced many organizations to navigate other complexities – like a dramatic decline in revenue due to shelter-in-place orders – just to remain solvent. To win the race long-term, companies must meet these challenges head-on and one way to do it is through innovation.

In part one of our Innovation blog series, we covered why Innovation is crucial during times of crisis. In part two, we will show you how the small steps you take today can help you keep up with current demands and prepare for innovation tomorrow. We will share a practical approach on how to develop innovative ideas to implement, discuss how to select the right ideas to implement, provide actionable processes and tips on how to implement the ideas, and check if the plans are working.

Truthfully, not all innovation is glamorous or earth-shattering. In business, most innovative ideas are small, incremental improvements that an organization commits to. There are numerous methodologies or approaches that can help you make huge strides towards innovation. One of the most effective yet practical approaches is Kaizen.

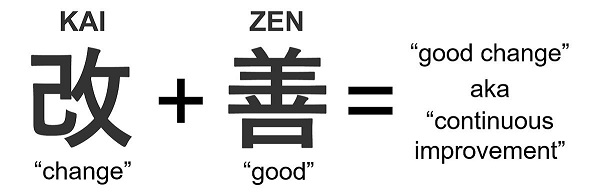

What is Kaizen?

Developed in Japan after WWII, Kaizen is a systematic business improvement approach that leads companies to continuously superior results. It is often used as a pillar of an organization’s long-term competitive strategy. When an organization encourages a Kaizen culture – small innovations on an ongoing basis – it paves the way for driving more significant breakthroughs.

The Japanese word kaizen means “change for better”, without inherent meaning of either “continuous” or “philosophy” in Japanese dictionaries and in everyday use. The word refers to any improvement, one-time or continuous, large or small, in the same sense as the English word “improvement”. However, given the common practice in Japan of labeling industrial or business improvement techniques with the word “kaizen”, particularly the practices spearheaded by Toyota, the word “kaizen” in English is typically applied to measures for implementing continuous improvement, especially those with a “Japanese philosophy”.

Kaizen lays the groundwork that encourages innovation by providing an action plan for solving problems, a steady stream of incoming ideas and empowering people in an organization to use them.

How Innovation is Achieved Through Kaizen

Drawing from over 35 definitions available online, innovation can best be described as “something new or improved that creates value.”

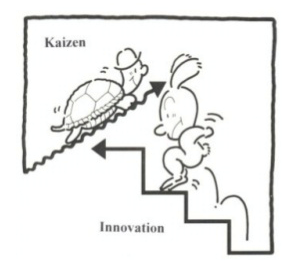

Both Kaizen and innovation depend on new ideas, iterative processes, problem-solving and stakeholders understanding that there is a better way to do things. Kaizen is primarily associated with incremental innovations because in its processes of continuous improvement, the induced changes are not radical, changes are gradual. In general, innovations are first obtained through a series of incremental changes in processes, and as it progresses, reach significant changes that generate innovation in processes, services, or products.

“Kaizen and Innovation are two major strategies people use to create change. Where Innovation demands shocking and radical reform, all Kaizen asks is that you take small, comfortable steps towards improvement.” – Robert D. Maurer, American physicist and inventor

Kaizen Starts with the Right Mindset

What makes Kaizen drastically different is the idea of shifting the mindset and creating a new organizational culture where small tweaks are made in the process, and they don’t only come from the top-down. One of the most crucial aspects behind Kaizen is the idea of ensuring each employee has the same mindset. Because of that, they’ll feel inspired and engaged in proposing and implementing changes within the organization.

Key Benefits of Kaizen:

- Teamwork

- Personal discipline

- Improved morale

- Quality circles

- Suggestions for improvement

Kaizen is truly based on the belief that everything can be improved, and nothing is status quo. It’s essential that all employees understand and respect this principle.

As a result, you’ll not only have team collaboration and team building, you’ll also develop commitment and consensus. Because you’ll be making small changes constantly, you’ll have the opportunity to learn with each change and then validate all the learnings.

Building a Team that Innovates by Creating a Kaizen Culture

It is essential to develop and instill in your employees to look for ways to drive improvements forward continually. Kaizen encourages healthy habits such as problem-solving, persistence, curiosity, workforce engagement, and challenging the status quo. To support a culture of innovation, encourage the following habits:

- Responsible Risk-taking. New is risky, but a workforce that is allowed to take some risks and encounter some failures is gaining knowledge that can drive future successes.

- Empowered input. By rewarding initiative and decision-making, your workforce and leaders are encouraged to change things for the better.

- Addressing challenges. When a problem arises, does your workforce look for solutions or look to management? When your team is focused on searching for problems, they’re always actively looking for solutions.

- Experimentation. Not every innovation will pan out the first time it’s implemented. By encouraging experimentation and measuring progress, ideas can be fine-tuned over time.

- Ongoing discussions. Teams that talk about the improvements they’re exploring, and who share lessons learned, are guiding future progress.

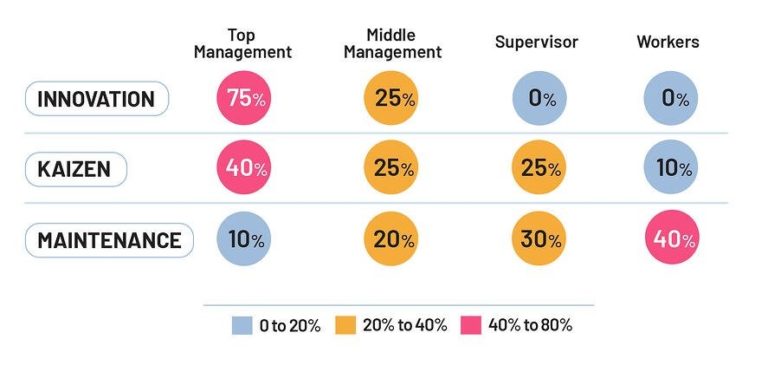

Involvement Across an Organization

This chart compares the percentages of the level of involvement for each type of employee across an organization. In Kaizen, involving many people across the organization is key:

Involve Your Customers and External Partners Too

Chances are, if you’re in business, there are customers you serve and partners you collaborate with. How you involve your customers and partners can also be a big part of your innovation culture and success. Here are some ideas to try out:

- Ask customers. If you simply ask your customers how you could improve your product or service, they will give you plenty of ideas for incremental innovations. Typically, they will ask for new features or that you make your product cheaper, faster, easier to use, available in different styles and colors, etc. Listen to these requests carefully and choose the ones that will payback.

- Observe customers. Do not just ask them, watch them. Try to see how customers use your products. Do they use them in new ways? This was what Levi Strauss saw when they found that customers ripped the jeans – so they brought a line of pre-ripped jeans. Heinz noticed that people stored their sauce jars upside down, so they designed an upside-down bottle.

- Use difficulties and complaints. If customers have difficulties with any aspect of using your product or if they register complaints, then you have a strong starting point for innovations. Make your product easier to use, eliminate the current inconveniences, and introduce improvements that overcome the complaints.

- Collaborate. Work with another company that can take you to places where you can’t go. Choose a partner with a similar philosophy but different skills. That is what Mercedes did with Swatch when they came up with the Smart car.

- Run a contest. Ask members of the public to suggest great new product ideas. Offer a prize. Give people a clear focused goal and they will surprise you with novel ideas. Good for innovation and PR.

- Use social networks. Follow trends and ask questions on groups like Twitter or Facebook. Ask what people want to see in future products or what the big new idea will be. Many early adopters are active on social network groups and will happily respond with suggestions. (Check out “Innovation Management’s” full list )

Putting Kaizen into Action

The Kaizen action plan is about organizing events that are focused on improving specific parts of the company to involve employees at all levels. Typically, Kaizen encompasses 4 phases as outlined by The Association for Supply Chain Management (ASCM):

- Phase 1: Preparation

- Phase 2: Training

- Phase 3: Implementation

- Phase 4: Follow-Up

Phase 1: Preparation

The most critical stage of any kaizen event is the preparation. Yet correctly defining the problem, goal and scope can be very challenging. Try this simple but effective approach. First, team leaders should ask the following:

- What is the purpose of the event?

- What process or value stream will be targeted?

- What are the desired outcomes?

- Who should be on the team?

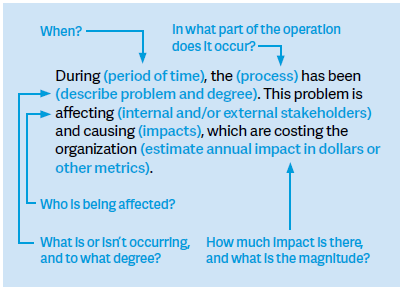

Next, create a problem statement. Answer these questions to define the problem:

- What is or isn’t occurring, and to what degree?

- Where in the process or product does it occur?

- Who does the problem affect?

- When did it occur, and has it occurred before?

- How much impact is there, and what is the magnitude in terms of frequency, cost, time, and customer satisfaction?

The following is a problem statement template that has been diagrammed to highlight these questions. Notice that there isn’t a “why” or anything about what actions will be taken.

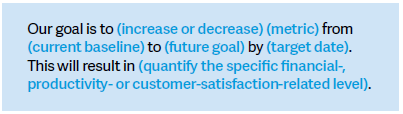

Next, consider the goal statement, which should address the issue in the problem statement. It quantifies the expected performance improvement and identifies the timing. A goal statement doesn’t mention the cause of the problem, nor does it say what actions will be taken. Remember to make your goal statement SMART — specific, measurable, achievable, relevant, and timely. Here is a template:

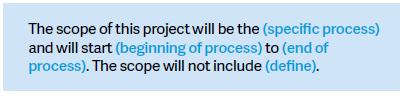

The next phase involves clarifying the project’s boundaries. The scope should delineate where the project starts and ends and identify what it includes and excludes. A typical scope statement would sound something like this:

(For the purposes of providing a high-level overview, we will cover just the first phase in our blog. Check out the full treatment by ASCM page.)

Not All Ideas Are Created Equal

“The way to get to good ideas is to get lots of ideas and throw the bad ones away,” Linus Pauling, American chemist

While it’s important to have a good process in place to ensure a steady stream of ideas, it’s even more important to select the right ideas to innovate. So what makes an idea a good idea? Sometimes good ideas just stand out to you; other times, it may not be as clear.

Here are some tips from SmartStorming:

“There are certainly common characteristics shared among all worthwhile ideas. But in most cases there will be more specific qualities that must be present for an idea to be considered highly effective for solving a particular challenge.”

The Common Elements of Good Ideas

- Different/Better – For a good idea to be good, it must be at least somewhat different from something else – whatever the new idea is attempting to replace. And it must offer some degree of improvement. Otherwise, it’s just an okay idea or a bad idea. It doesn’t necessarily have to be new (as in never before done – as in “innovative”), just different from what has been done before for the specific challenge.

- Delivers Value – “Value” is an interesting word in that it requires two connected elements. First, the idea must do something better – faster, cheaper, easier, more elegantly, more powerfully, more effectively, more efficiently. But that improvement must also be something somebody actually wants. All of the examples given earlier (and pretty much every other legendary product or marketing blunder) failed because nobody really wanted the improvement provided, or at least not at the expense of something else more important. Value is, by definition, something “valued.” And it is an essential component of a good idea.

- Doable – A flying car or a home teleportation chamber would be nifty. But unfortunately, both defy the currently accepted laws of physics. For an idea to be good, it has to be possible. It might seem obvious, but if you sit through enough brainstorm sessions, you will hear lots of impossible suggestions.

- Acceptable Cost-Benefit – If the idea costs more to implement than it can deliver in terms of value, it is impractical. This applies not just to financial cost, but time, resources, energy, etc. If no one is willing to pay the price for whatever benefit the idea delivers, it’s not a good idea.”

How To Know If Kaizen is Working

The sheer number of ideas alone is not a reliable metric to measure the impact of innovation. It is important to put other metrics in place to gauge the effectiveness and impact to the organization. Some ideas include:

- ROI metrics – These metrics address resource investments and financial returns. They help recognize the value of an innovative initiative and justify the organization’s overall investment in innovation.

- Leadership metrics – These metrics focus on the behaviors that those in leadership roles must exhibit to support an organization’s innovation culture.

- Organizational capability metrics – These metrics focus on the infrastructure and process of innovation. They can help projects build repeatable approaches to innovation.

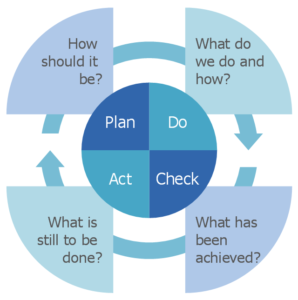

Once relevant metrics are in place, it is important to regularly check-in and analyze results. The PDCA cycle (Plan, Do, Check, Adjust) is an iterative four-step management method used in business to drive progress and gauge success:

Plan

Establish objectives and processes required to deliver the desired results.

Do

The do phase allows the plan from the previous step to be done. Small changes are usually tested and data is gathered to see how effective the change is.

Check

During the check phase, the data and results gathered from the do phase are evaluated. Data are compared to the expected outcomes to see any similarities and differences. The testing process is also evaluated to see if there were any changes from the original test created during the planning phase. If the data is placed in a chart, it can make it easier to see any trends if the PDCA cycle is conducted multiple times. This helps to see what changes work better than others and if said changes can be improved as well.

Act

Also called “Adjust”, this act phase is where a process is improved. Records from the “do” and “check” phases help identify issues with the process. These issues may include problems, non-conformities, opportunities for improvement, inefficiencies and other issues that result in outcomes that are evidently less-than-optimal. Root causes of such issues are investigated, found and eliminated by modifying the process. Risk is re-evaluated. At the end of the actions in this phase, the process has better instructions, standards, or goals. Planning for the next cycle can proceed with a better base-line. Work in the next Do phase should not create a recurrence of the identified issues. If it does, then the action was not effective.

The PCDA Cycle

Improve, Rinse, and Repeat – A Cycle for Continuous Improvement

In summary, there are seven steps you can follow to create a cycle of continuous improvement based on Kaizen:

- Get employees engaged and involved. Employees should feel like part of the process and collaborate to test new solutions.

- Find problems. Make sure all employees feel empowered to find and talk about problems. You can also brainstorm possible problems.

- Create a solution. Empower and encourage everyone in the organization to create new solutions to problems or even improve old ways of doing things.

- Test the solution. Implement the winning solution chosen by the team, and test it in a pilot program

- Measure and analyze the results. This is one of the most important parts. We need to be able to measure and analyze the results and validate our learnings and assumptions. This stage will also help to engage the team.

- Standardize. If the organization and employees are satisfied with the results, standardize them and make sure everyone in the team uses the new solution.

- Repeat. Don’t let the Kaizen habits die. You should make sure your team will continue to iterate on that until it becomes a habit.

Remember, innovation is not just an initiative; it’s a business process that your organization commits to. In the legal industry, where change is often met with resistance, innovation might seem out of reach. Perhaps a more practical way to approach innovation – especially during a crisis like the COVID-19 pandemic we are currently experiencing – is to utilize the downturn to take the small but necessary steps to investigate and improve your business processes. Once you’ve laid the groundwork to create a Kaizen culture within your organization, it becomes more achievable to implement breakthrough innovations or transformations successfully.

What small, incremental steps can your organization take today to help make leaps and bounds with innovation tomorrow?